- info@dndap.com

- +91 8200372402

- Follow Us

Quality

Attitude for “zero defects”

- Refresing to get such a personal touch.

- Duis aute irure dolor in reprehenderit in voluptate.

- Velit esse cillum dolore eu fugiat nulla pariatur.

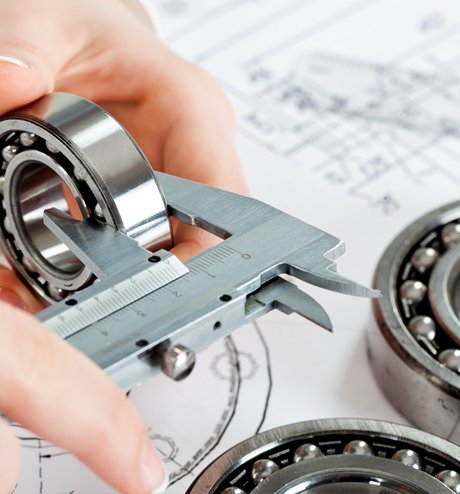

Meet industrial quality standard

- Setup, In-Process and Final Inspection

- First Article Inspection (FAI)

- Statistical Process Control reports (SPC)

- PPAP documents

- Process studies & sampling techniques

- Continuous improvement

- Scheduled gauge calibration

Quality and service is our passion.

Our company is certified to ISO 9001:2015 standards. As such, we are continuously looking for ways to improve our products and processes. We’ve developed a comprehensive inspection and testing procedure to ensure each of our machined products meets customer specifications and standards. Some of the inspection and testing instruments we employ are:

-

Keyence image measuring system

Mitutoyo Coordinate Measuring Machines

-

Mitutoyo Optical Comparator

-

Rational Optical Measuring System

-

Rockwell Hardness Tester

-

Rockwell Superficial Hardness Tester

-

Vickers Hardness Tester

-

Surfcom Surface Roughness Tester

-

Universal Concentricity Gages

Micrometers & Calipers

-

Dial Indicator

-

Magnifiers & Microscopes

-

Pin & Plug Gages

-

Thread Plug & Ring Gages

-

3-Wire Thread Measuring System

-

Salt Spray Tester